- GST No. 24AALFR9270N1ZH

- Send SMS

- Send Email

Industrial Mineral

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Barite Crystal, Barite Stones, Bauxite Ore, Black Coal, Calcined Bauxite, Calcite Lumps, Copper Slag, Dolomite Stones, Feldspar Stone, Garnet Powder, Laterite Soil, Laterite Stone, Laterite Stones, Manganese Ore, Mica Flakes, Quartz Crystal, Silica Sand and Mineral Powder from Kutch.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| State | Lump |

| Whiteness | White |

| Purity | >95% |

| BaSo4 | 92% minimum |

| Form | Lumps |

| Grades | 4 |

| Packing Size | 50 kg |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Applications | Paints, Rubber, Drilling, Cosmetic, Paper |

| BaSo4 | 92% minimum |

| Form | Lumps |

| Grades | 4 |

| Packing Size | 50 kg |

| Usage | Industrial |

Baryte is generally white or colorless, and is the main source of barium. Barite is found in the southern parts of India. It is extracted by both surface and underground mining.

It is non-toxic and physically and chemically non-reactive. It is available in hydrous form as well as lumps.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Feature | Highly Effective, Longer Shelf Life |

| Condition | Crushed Lumps |

| Alumina | 25-50% |

| Packaging Size | 50kg |

| Applications | Abrasives, Refractories |

| Refractory Temperature | 1790 ℃ |

| Melting Temperature | 2000-2200℃ |

| Specific Gravity | 3.45g/cm3 |

Bauxite, an aluminium ore, is the world’s main source of aluminium. It consists mostly of the minerals gibbsite, boehmite and diaspore, mixed with the two iron oxides goethite and haematite.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Purity | 99% |

| Feature | High Fast Flaming, High Reliability, Longer Shelflife |

| Volatile Matter | 15-30%, 30-45%.45-60% |

| Ash Content | 40-60%, 60-80% |

| Moisture | 40% |

| Calorific value | 6000kcal/kg, 7000kcal/kg, 8000kcal/kg |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Form | Lumps |

| Packaging Type | Plastic Bags |

| SiO2 | 5% |

| Fe203 | 10-20% |

| Packaging Size | 50Kg |

| TiO2 | 5-10% |

| Al203 | 90% |

| Applications | Abrasives, Refractories, Road surfacing |

Calcination is a process of heating, hence calcined bauxite is obtained by heating the high grade ore of the bauxite. Heating further removes the moisture content from the ore and thus results in the increase of the alumina content.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Color | White |

| Form | Lumps |

| Packaging Size | 25-50 Kg |

| White | 84-97 % |

| MgO | 30-32 % |

| Purity | 98% |

| Grade | Industrial |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Material | Shot Blasting Grid |

| Application | Industrial |

| Color | Dark-black |

| Packaging Type | Plastic Bags |

| Standard | Technical |

| Abrasive Grain Sizes | 0.2-5mm |

| Packaging Size | 25-50Kg |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Application | Industrial Use |

| Capacity(t/h) | 100 TON/H |

| Applications | Steel industry, Refractory, Glass, Ceramic |

| Available CaO | 31% Min |

| MgO | 21 % Min |

| SiO2 | 0.19% Max |

Dolostone is the main source of the mineral dolomite. It is an anhydrous carbonate mineral composed of calcium magnesium carbonate. It is used as an ornament stone, construction aggregate and main source of magnesium oxide.

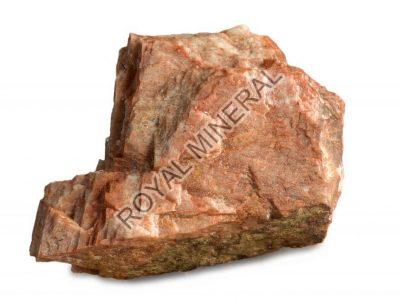

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Material | Feldspar |

| Thickness | 40-80mm |

| Color | Brown |

| Feature | Durable, Light In Weight |

| Finishing | Polished |

| Stone Form | Lumps |

| Applications | Ceramic, Sanitaryware, Catalyst, Decorative stone |

Feldspar is most common rock-forming mineral. It generally white or very light in colour. The feldspar refers to the group of Aluminium silicate of potassium, sodium and calcium. Among the numerous rocks in which they are present the feldspars are particularly abundant in igneous rocks.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Application | Polishing, Smoothing |

| Color | RED |

| Feature | Durable, Highly Abrasive, Reusable, Rust Resistance |

| Form | Dust |

| Country of Origin | India |

| Applications | Abrasives, Sand Blasting, Water jet cutting |

Garnet is pure and natural sand. Of the six major varieties of Garnet (Almandine, Andradite, Grossularite, Pyrope, Spessartite, Uvarovite), Almandine is the best abrasive Garnet with the composition of 3FeO, AI203, ESIO2. As Garnet has low content of free silica in it, it is widely used in sand blasting and waterjet cutting.

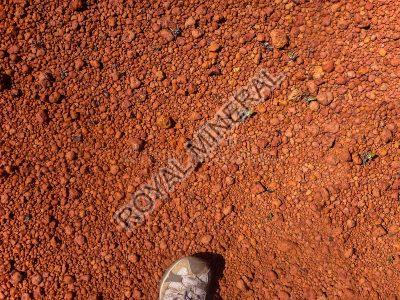

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Red | Red |

| Alumina | 7.93 % |

| Titania Oxide | 1.29 % |

| Sodium Oxide | 0.17 % |

| Silica | 16% |

| Potassium Oxide | Less than 0.10 % |

| Magnesium Oxide | Less than 0.10 % |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Application | Industrial Use |

| Use | Construction |

| Form | Blocks |

| Moisture | 0.05% |

| Al2O3 | 75% |

| Specific Gravity | 3.45g/cm3 |

| Refractory Temperature | 1790 ℃ |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Color | Red |

| Feature | Fine Finished, Hard Struecture |

| Surface Finishing | Polished |

| Stone Form | Solid |

| Stone Type | Laterite |

| Moisture | 0.05% |

| Al2O3 | 75% |

| Specific Gravity | 3.45g/cm3 |

laterite is a polymetallic ore and it is rich in iron oxide. it is formed from a variety of rocks that undergo stray oxidizing and leaching conditions. laterite is typical clay like material and porous. the colors of laterite vary from red, reddish-black, brown, yellow and blackish-brown. laterite also in short can be called as a rock product that is formed in response to a set of physiochemical conditions. it has a number of uses in industries nowadays.

applications

- laterite is widely used as a road material. it is also used as stones for building due to its strength and hardness.

- laterite is used as an additive in cement industry. it is also used for the removal of fluoride from contaminated drinking water. laterite is also a source of iron, manganese, and nickel and chromium production.

- one of the few applications of laterite is that it is a vast source of useful minerals. these minerals can be easily extracted from it and thus, ensures that laterite on the whole can be indirectly used in various fields and has a vast amount of applications. also laterite is home for trace elements like gallium and vanadium.

type of production process at royal mineral

- laterite is first air-dried. this is quiet essential. after this, the particles are grinded and sieved to produce fine materials. grinding of laterite is done for breaking the huge lumps of laterite rocks. this is done with the help of hammer.

- sieving of laterite is done to get the fine particles. now impurities are removed. this is done by sweeping, brushing or scraping processes. it is then casted into a trough and sampled to produce the required laterite form. this is what ultimately is manufactured to the clients. the production process mainly consists of varied procedures.

- this includes batching, mixing of varied components along with the laterite particles, then casting of the compound that is formed which has laterite and then ultimately its manufacturing. the entire procedure is detailed and helps us to provide the best laterite based materials.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Color | Silvery Grey |

| Form | Lumps |

| Chemical Composition | Fe2O3, MnO2 |

| Dimensions | 10-20Mm, 10-30Mm |

| Colour | Grey |

| Usage | Chemical Industry |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Shape | Flake |

| Application | Cosmetics |

| Oil Absorption | 48-500g/100g |

| Brand Name | ROYAL MINERAL |

| K2O Content (%) | 9-11% |

| MgO Content (%) | 0.3-2% |

| Al2O3 Content (%) | 20-33% |

| Packaging Details | Mica flakes are packed in 50 kg HDPE bag or 1 mt jumbo bag as per customer's choice. |

| CaO Content (%) | 0.02-0.77% |

| Place of Origin | Rajasthan, India |

| Supply Ability | 1000 Metric Ton/Metric Tons per Month |

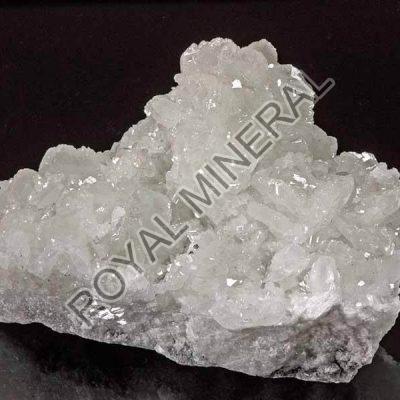

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Melting point | 1670°C |

| Stone Name | Quartz (White And Colored) |

| Dimensions | 001 - .007 - 1. 5 |

| Fe203 | 0.02% max. |

| CaO | 0.11% |

| MgO | 0.08% |

| Sieving rate | 97% |

| Al2O3 | 500 ppm |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| TEST REPORT OF SILICA SAND | |

| Test report of Silica Sand(Foundry Grade) | |

| Color | Natural Color |

| Brand Name | R-BOND |

| MgO Content (%) | <0.01% |

| P2O5 Content (%) | <0.01 |

| Port | MUNDRA |

| Place of Origin | Gujarat, India |

| Supply Ability | 10000 Metric Ton/Metric Tons per Month |

| Model Number | SILICA SAND |

| Packaging Details | STANDARD EXPORT PACKING |

| MgO Contain | 0.55% |

| CaO Content | <0.05% |

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer, Buying House |

| Feature | Gives Shining, Hair Damage Protection, No Added Artificial Color |

| Form | Powder |

| Packaging Type | Plastic Packet |

| Packaging Size | 250gm, 500gm |

| Applications | Cosmetic, Ceramic, Paint, Plastic, Detergent |

| Fe2O3 | 0.5% Maximum |

| CaO | 0.5-12% (As per Requirement) |

| CaCO3 | 1.0-35% (As per Requirement) |

Magnesium silicate has a trade name of Talc. It possesses lubricating properties, high luster and sheen. The colour of the material varies from the pure white to silvery white. It is one of the softest mineral and has a soapy feel.